Over the course of 12 months, we stripped the old backup generator room, steam cleaned the walls, re-poured the floor and rewired it.

While Hawklaw was operational, the back-up generator room housed a large diesel generator powerful enough to run the entire station in the event of mains power failing.

Little of the original equipment remained in this room when we bought Hawklaw in 2012 and the room was damp, dirty and a haven for pigeons, mice and even rats.

Step 1 – stripping the room

Although the actual generator was long gone, much of the ancillary fixtures to run it were still evident, including the giant air intake and exhaust. Both of them required a winch to safely lower them down from the roof.

The next issue to tackle was how to remove the raised plinth. This was 12 inch deep, reinforced concrete pad laid on sand and connected to 12 reinforced concrete piles. The reason for such a heavily engineered plinth was to prevent vibrations from the diesel generator vibrating the entire engineer’s garage.

We removed it by first sawing the pad into sections with a stihl saw, then using a Hilti TE1000 heavy duty breaker to remove the sections. This was very dusty and back breaking work.

Removing and rerouting the electrics

iron light switch

One of the things I love about Hawklaw is figuring out how everything worked and wherever possible, we like to renovate and reuse old things we find for example, this original Crabtree cast iron light switch that we reconditioned and is now in use in our Robin Hood Room.

The key objective was to install modern, ducted electrics in the room, but firstly, I wanted to preserve as many artefacts as I could, and temporarily reroute electrics while some of the other works continued in the room.

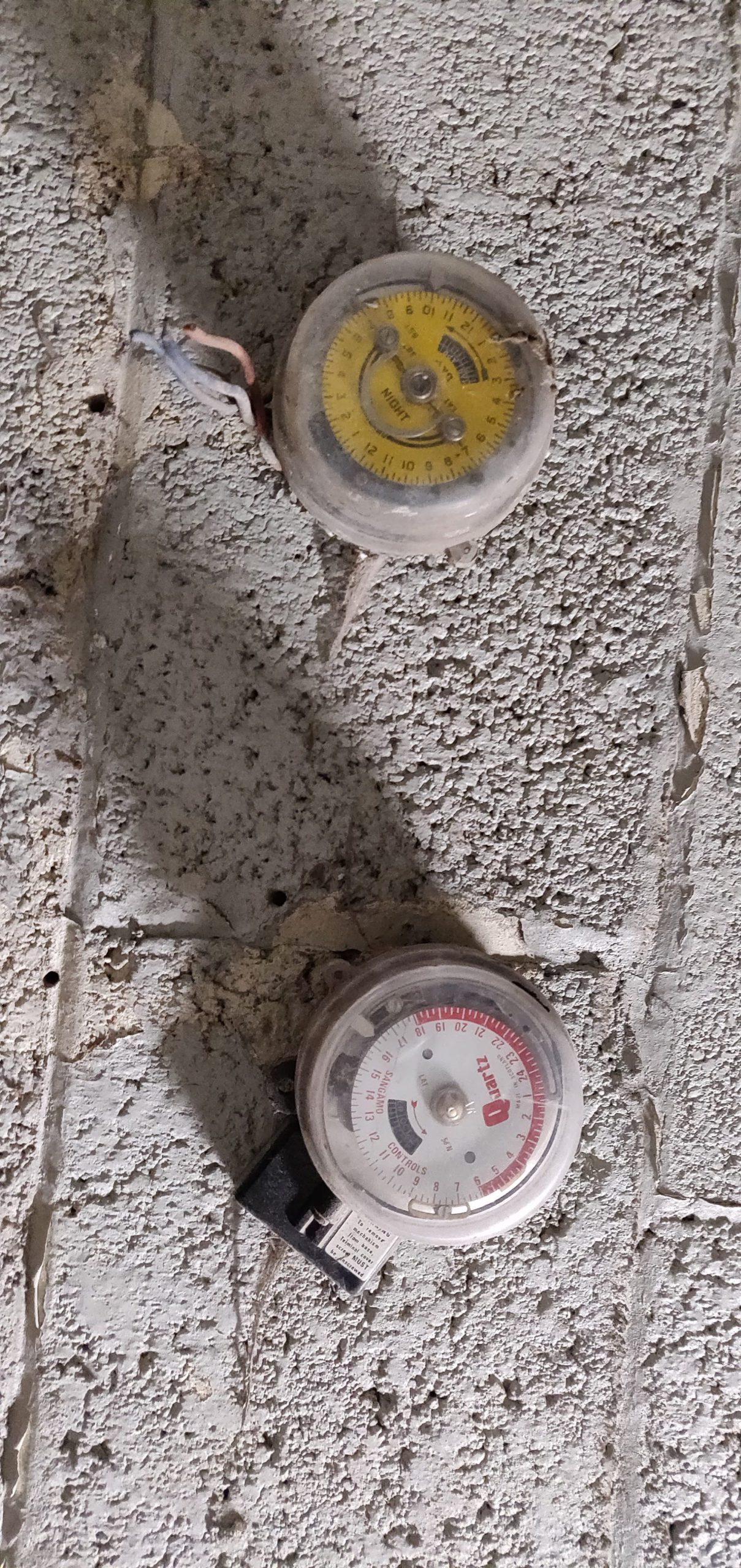

We discovered 2 Sangamo timers, connected to lighting circuits which were presumably used to control the exterior lighting on the site. These controls were relatively modern and able to adjust for varying hours of darkness as the seasons changed.

To be continued…